For most modern two-stroke engines, 50:1 is the correct and safest ratio when you use a high-quality oil that meets modern standards and follows the manufacturer’s specification.

40:1 exists as a durability buffer for older designs, heavier-duty cycles, or mixed equipment fleets.

32:1 is primarily for older or high-load engines that were engineered around higher oil content and looser tolerances.

More oil is not automatically better. Each ratio reflects a balance between lubrication, temperature control, deposits, and emissions.

How Two-Stroke Engines Really Get Lubricated

A two-stroke engine has no oil sump and no pressurized lubrication system. Every bearing surface, ring face, wrist pin, and crank journal relies on oil that is carried in with the fuel, atomized, briefly forms a lubricating film, and then burns.

Lubrication quality, therefore, depends on four variables working together: oil quantity, oil chemistry, operating temperature, and load duration.

Because the oil is consumed, increasing the oil ratio does two things at the same time. It increases the thickness and durability of the lubricating film, but it also increases the amount of oil that must burn and exit through the exhaust port.

This is the fundamental trade-off behind every premix ratio.

What the Numbers Actually Mean

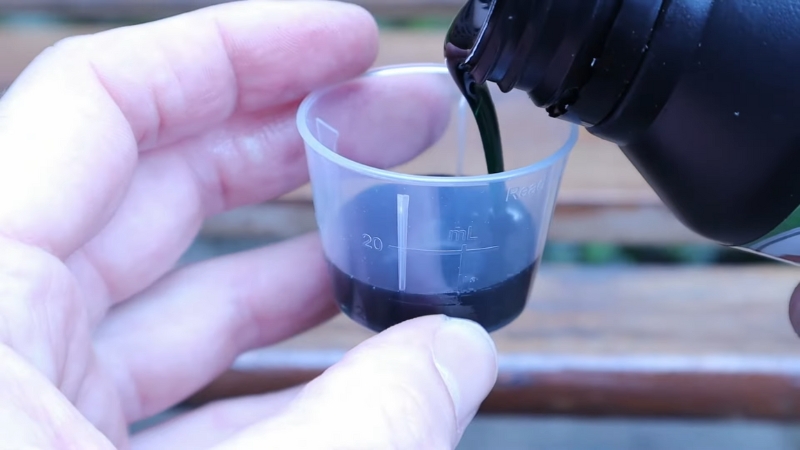

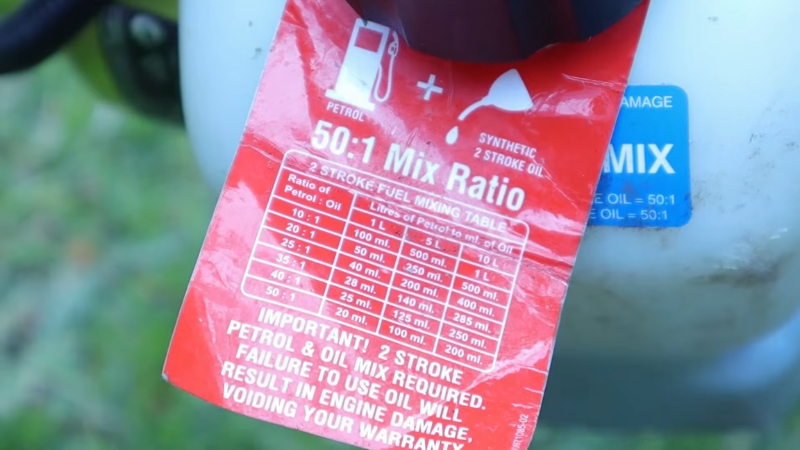

A premix ratio expresses how much gasoline is mixed with one part oil by volume.

Ratio

Oil percentage

Oil per US gallon

50:1

2.0%

~2.6 fl oz

40:1

2.5%

~3.2 fl oz

32:1

3.125%

~4.0 fl oz

The jump from 50:1 to 32:1 is not small. It represents over 50 percent more oil entering the engine and exhaust system.

Why 50:1 Became The Modern Standard

Most modern handheld two-stroke engines are designed around 50:1. This shift did not happen because manufacturers wanted to reduce engine life. It happened because oil technology and engine design evolved together.

Modern two-stroke oils meeting standards such as JASO FD or ISO-L-EGD provide stronger film strength, higher thermal stability, and far better detergency than older mineral oils. At the same time, modern engines use tighter tolerances, improved ring metallurgy, and port designs that are highly sensitive to deposits.

At 50:1, these engines receive enough lubrication while keeping piston crowns, ring grooves, exhaust ports, and spark arrestors clean over long service intervals.

Another unavoidable factor is emissions. Increasing oil content significantly increases particulate matter and visible smoke. Modern engines are certified for low-smoke operation, and excessive oil disrupts that balance.

From a design standpoint, 50:1 is where lubrication adequacy, cleanliness, and emissions intersect when high-quality oil is used.

What Changes Inside The Engine At 40:1

40:1 exists as a middle ground. It delivers a thicker oil film and greater margin against scuffing during sustained high load, high temperature operation, or when oil quality is uncertain.

This is why some manufacturers and fleet operators recommend 40:1 as a universal ratio across mixed equipment, especially when older engines are still in use.

Mechanically, the additional oil increases bearing and ring lubrication headroom, but it also increases deposit formation.

Carbon accumulation in ring lands and exhaust ports accelerates faster at 40:1 than at 50:1, particularly in air-cooled engines that already operate near thermal limits.

Over time, this can reduce exhaust flow and contribute to ring sticking if detergency is insufficient.

40:1 is therefore a conservative durability choice, not an upgrade for engines explicitly designed for 50:1.

Why 32:1 Still Exists And When it Actually Makes Sense

@twowheelhouse 32:1 premix #dirtbike #supermoto #trending #fyp #250cc #twostroke #fourstroke #kawasaki ♬ La Niña Está Triste (feat. Jesús “Tuti” Martínez) – Leo Dan

32:1 is rooted in older engine architecture. Many legacy two-stroke engines were designed when oils had lower film strength and poorer detergency.

These engines often had looser clearances, different port timing, and materials that relied on a heavier oil presence to prevent metal-to-metal contact.

In high-performance or sustained wide-open-throttle applications such as older dirt bikes or certain racing engines, 32:1 provided thermal and lubrication stability under extreme loads.

The cost was higher smoke output, more frequent decarbonization, and shorter exhaust maintenance intervals.

Using 32:1 in a modern consumer engine that specifies 50:1 does not add protection in a meaningful way. Instead, it increases the risk of fouled plugs, clogged spark arrestors, carboned ports, and degraded emissions performance without improving wear outcomes.

Oil Quality Matters as Much as The Ratio

Premix ratio and oil quality are inseparable. A modern full synthetic or high-grade semi-synthetic oil formulated to JASO FD or ISO-L-EGD standards can safely operate at lower oil percentages because its film strength and detergency compensate for reduced volume.

Conversely, lower-quality oils often require higher ratios simply to maintain a survivable lubricating film.

This is why marine TC-W3 oils, designed for water-cooled outboards, are not always ideal substitutes for air-cooled handheld equipment. Air-cooled engines run hotter, and oil chemistry must tolerate higher piston crown and ring temperatures without forming hard deposits.

Ratio, Jetting, And The Common Tuning Confusion

Changing the oil ratio changes the proportion of gasoline in the premix. With more oil present, there is slightly less gasoline per unit volume, which can alter effective combustion characteristics in carbureted engines.

In practice, the effect is small for modest ratio changes, but in performance or racing applications, any ratio change should be treated as a tuning variable. This is why experienced builders evaluate plug color, exhaust temperature, and piston wash when ratios are altered.

For stock consumer equipment, following the specified ratio avoids this complexity entirely.

When To Use Each Ratio in Real Life

Engine type and use

Recommended ratio

Modern chainsaws, trimmers, and blowers with high-quality oil

50:1

Mixed fleets including older engines

40:1

Older designs built around higher oil content

32:1

Break-in periods

Follow manufacturer guidance

Racing or sustained WOT engines

Engine-specific, often richer

The Bottom Line

View this post on Instagram

Two-stroke premix ratios are not opinions or folklore. They are engineering decisions based on oil chemistry, engine materials, thermal behavior, and emissions constraints.

50:1 is correct for most modern engines when paired with the right oil. 40:1 provides a durability buffer when conditions or equipment demand it. 32:1 belongs to older or specialized engines that were designed for it.

Choosing the right ratio is not about adding more oil for peace of mind. It is about matching oil quantity and quality to the engine’s design assumptions so lubrication, cleanliness, and longevity stay in balance.