Solar panels are made primarily from silicon-based solar cells, protected by tempered glass, supported by aluminum frames, and interconnected with copper and silver conductors, while encapsulation layers and polymer backsheets provide insulation, durability, and weather resistance.

Modern photovoltaic panels are engineered composites rather than single-material products, and each layer serves a specific electrical, structural, or protective function that directly affects efficiency, lifespan, cost, and recyclability.

Silicon – the Core Material that Converts Sunlight Into Electricity

Silicon is the foundational material in more than 90 percent of solar panels installed globally today. It is used to manufacture photovoltaic cells, which convert sunlight into electrical energy through the photovoltaic effect.

Silicon is chosen not because it is exotic, but because it is abundant, chemically stable, and has electronic properties that allow it to act as a semiconductor. When photons strike silicon atoms, electrons are released and guided through an electric field created by doping the silicon with boron and phosphorus.

There are three main forms of silicon used in solar panels, each with different manufacturing processes and performance characteristics. Monocrystalline silicon is produced from a single, continuous crystal structure grown using the Czochralski process.

This produces uniform electron flow, higher efficiencies, and a distinctive black appearance. Polycrystalline silicon is made by melting multiple silicon fragments together, resulting in a less uniform crystal structure and slightly lower efficiency.

Amorphous silicon, used mainly in thin-film panels, lacks a crystalline structure entirely and absorbs light differently.

Silicon type

Manufacturing method

Typical efficiency

Market share

Monocrystalline

Single-crystal ingot slicing

20–23%

~70%

Polycrystalline

Cast multi-crystal blocks

15–18%

~20%

Amorphous (thin film)

Vapor deposition on the substrate

8–12%

<5%

Monocrystalline silicon dominates utility-scale and residential installations because higher efficiency reduces land use and balance-of-system costs. Polycrystalline silicon has declined sharply since 2018 as monocrystalline production costs fell due to larger wafers and improved cutting methods.

Doping Materials – Boron and Phosphorus

Pure silicon cannot generate usable electricity on its own. It must be chemically altered through a process called doping, where trace amounts of other elements are introduced to control electron movement.

Boron is used to create positively charged layers, while phosphorus creates negatively charged layers. Together, they form the p-n junction that drives electron flow when sunlight hits the cell.

The quantities involved are extremely small, measured in parts per million, but they are critical to performance. Changes in doping concentration affect voltage, current density, and temperature sensitivity.

Advanced cell architectures such as PERC, TOPCon, and heterojunction cells rely on more precise doping profiles and additional passivation layers to reduce electron recombination losses.

Dopant element

Function in cell

Typical concentration

Boron

Creates a p-type silicon layer

1–10 ppm

Phosphorus

Creates an n-type silicon layer

1–10 ppm

Silver and Copper – Electrical Conductors Inside the Panel

Once electrons are released within the silicon cell, they must be collected and transported out of the panel. This is done using ultra-thin metal conductors printed onto the surface of each cell.

Silver paste is used to form front-side grid lines and rear contacts because of its excellent conductivity and corrosion resistance. Copper is used primarily in busbars, interconnections between cells, and external wiring.

Silver is one of the most expensive materials in a solar panel by weight, even though it makes up less than one percent of total mass.

In 2010, an average solar panel used over 400 milligrams of silver per cell. By 2024, this figure dropped below 100 milligrams due to narrower grid lines, copper plating techniques, and improved screen printing.

Material reduction has been a key driver of cost declines across the industry.

Metal

Location in panel

Reason for use

Silver

Cell contacts

High conductivity, corrosion resistance

Copper

Interconnects, wiring

Lower cost, good conductivity

Tin

Solder alloys

Low melting point

Tempered Glass – Protection and Light Transmission

View this post on Instagram

The front surface of most solar panels is made from tempered low-iron glass. This glass must serve two opposing functions.

It needs to be strong enough to protect fragile silicon cells from hail, wind, snow loads, and debris, while also allowing as much sunlight as possible to pass through with minimal reflection or absorption.

Low-iron glass is used because standard glass contains iron impurities that give it a green tint and reduce light transmission. Solar glass typically achieves over 91 percent transmittance.

The tempering process increases mechanical strength and causes the glass to shatter into small, blunt fragments rather than sharp shards if broken.

Glass property

Typical value

Thickness

3.2 mm

Light transmittance

91–93%

Impact resistance

IEC 61215 compliant

Snow load rating

5400 Pa

Some premium panels now use anti-reflective coatings or textured glass to reduce surface glare and improve energy yield, particularly in low-angle sunlight conditions.

Encapsulation Materials – EVA and POE

Between the glass and the solar cells lies the encapsulant layer. Its role is to bond the cell stack together, cushion mechanical stress, and electrically insulate the cells from moisture and oxygen.

The most common encapsulant is ethylene-vinyl acetate, known as EVA. It is heated during lamination to form a durable, rubber-like seal around the cells.

In recent years, polyolefin elastomer (POE) has gained adoption, particularly in bifacial and high-voltage panels. POE offers better resistance to moisture ingress and electrical degradation, reducing the risk of potential-induced degradation in large installations.

Encapsulant

Advantages

Limitations

EVA

Low cost, proven durability

Higher moisture permeability

POE

Better insulation, lower degradation

Higher material cost

Backsheet Materials – Polymers that Protect from Behind

The back of a solar panel is sealed with a multilayer polymer sheet known as the backsheet. Its purpose is to protect internal components from moisture, UV radiation, and electrical leakage.

Traditional backsheets are made from combinations of polyethylene terephthalate (PET) and fluoropolymers such as PVF or PVDF.

In bifacial panels, the backsheet is replaced with a second layer of tempered glass, allowing light to enter from both sides. This increases energy output by 5 to 20 percent, depending on ground reflectivity.

Backsheet type

Typical use case

Durability

PET/PVF laminate

Standard residential panels

25–30 years

PET/PVDF laminate

Harsh environments

30+ years

Glass-glass

Bifacial systems

30–35 years

Aluminum Frames – Structural Support and Mounting

Most solar panels are framed with anodized aluminum. Aluminum is lightweight, corrosion-resistant, and easy to extrude into precise profiles.

The frame provides rigidity, protects the edges of the glass, and allows the panel to be mounted securely to racking systems.

The anodizing process adds a protective oxide layer that prevents corrosion in coastal and industrial environments. Frameless panels exist, but they are less common due to handling and mounting challenges.

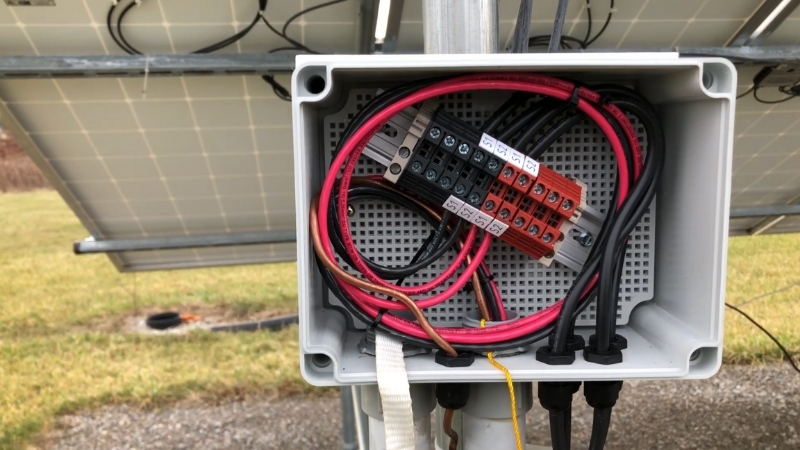

Sealants and Junction Boxes – Small Components with Critical Roles

Silicone-based sealants are used around the panel edges and junction box to prevent water ingress. The junction box, typically made from durable plastic polymers, houses the electrical connections and bypass diodes.

Bypass diodes are essential for preventing hot spots when part of a panel is shaded.

Component

Material

Purpose

Edge sealant

Silicone polymer

Moisture protection

Junction box

UV-resistant plastic

Electrical output

Bypass diodes

Silicon semiconductor

Prevent overheating

Materials Used in Thin-Film Solar Panels

Thin-film panels use different semiconductor materials instead of crystalline silicon. Cadmium telluride, copper indium gallium selenide, and amorphous silicon are deposited in extremely thin layers on glass or metal substrates.

These panels require less raw material and perform better in high temperatures, but generally have lower efficiency and more complex recycling considerations.

Thin-film type

Semiconductor material

Efficiency range

CdTe

Cadmium telluride

17–19%

CIGS

Copper indium gallium selenide

15–18%

a-Si

Amorphous silicon

8–12%

Cadmium-based panels are tightly regulated due to toxicity concerns, though encapsulation and recycling programs mitigate environmental risk.

Environmental and Recycling Considerations

@thegarbagequeen What are solar panels made of? ☀️🤔 The main components are silicon, glass, aluminum, and plastic, but they can also include other critical minerals depending on the type and manufacturer. Just like with any form of energy, there are pros and cons. Solar won’t work everywhere, and the manufacturing of the panels still contributes to climate change. But that doesn’t mean solar is inherently bad. People around the world are working towards making the industry more sustainable by developing better recycling methods, finding alternatives for materials, and retooling factories to be run on clean energy. #SolarEnergy #SolarPanels #SolarPanel #CleanEnergy #RenewableEnergy #ClimateChange #ClimateCrisis #ClimateAction #ClimateSolutions ♬ original sound – Alaina Wood

A typical silicon solar panel is composed of approximately 75 percent glass, 10 percent aluminum, 5 percent polymers, and less than 1 percent precious and specialty metals. This composition makes mechanical recycling feasible, though chemical separation of silicon and silver remains energy-intensive.

By 2030, global solar panel waste is expected to exceed 8 million metric tons, rising to over 78 million metric tons by 2050, according to international energy agencies. Material recovery rates above 90 percent are technically achievable with modern processes, particularly for glass and aluminum.

Material Trends Shaping the Future of Solar Panels

Ongoing research focuses on reducing silver content, replacing it with copper, improving encapsulants to extend panel lifespans beyond 30 years, and developing perovskite-silicon tandem cells that use additional semiconductor layers to boost efficiency above 30 percent.

These innovations aim to reduce material intensity per watt while increasing total energy output.

The materials used to make solar panels are not static. They reflect decades of incremental engineering improvements driven by cost pressure, durability requirements, and environmental constraints.