Solar panel recycling is a multi-step industrial process that separates glass, aluminum, silicon, copper, silver, and polymers from end-of-life photovoltaic modules using mechanical, thermal, and chemical treatments.

Modern recycling facilities can recover between 85 and 95 percent of a panel’s total mass, depending on panel type and recycling technology.

As global solar capacity installed before 2015 begins to retire, recycling is shifting from a niche activity into a regulated waste stream with defined costs, legal obligations, and rapidly evolving technology.

Why Solar Panel Recycling Is Becoming Unavoidable

Most photovoltaic panels installed during the early solar boom were designed for 25–30 years of service. Panels deployed in large numbers between 2010 and 2015 are now entering failure, replacement, or repowering cycles.

According to projections by the International Renewable Energy Agency, cumulative global PV waste is expected to exceed 8 million metric tons by 2030 and could reach 70–80 million tons by 2050 if current installation rates continue.

Recycling is not driven only by waste volume. Panels contain materials with measurable economic and strategic value, including aluminum frames, copper wiring, silver conductors, and high-purity silicon.

At the same time, panels contain encapsulants and backsheets that cannot be landfilled freely in many jurisdictions due to environmental compliance rules. This combination of volume, regulation, and material recovery economics is what has forced recycling infrastructure to scale.

What a Solar Panel is Made Of and Why Separation is Difficult

@thegarbagequeen What are solar panels made of? ☀️🤔 The main components are silicon, glass, aluminum, and plastic, but they can also include other critical minerals depending on the type and manufacturer. Just like with any form of energy, there are pros and cons. Solar won’t work everywhere, and the manufacturing of the panels still contributes to climate change. But that doesn’t mean solar is inherently bad. People around the world are working towards making the industry more sustainable by developing better recycling methods, finding alternatives for materials, and retooling factories to be run on clean energy. #SolarEnergy #SolarPanels #SolarPanel #CleanEnergy #RenewableEnergy #ClimateChange #ClimateCrisis #ClimateAction #ClimateSolutions ♬ original sound – Alaina Wood

A standard crystalline silicon solar panel is not a simple slab of glass and metal. It is a laminated composite engineered for durability, not disassembly. Roughly 70–75 percent of the panel by weight is tempered glass.

The remainder includes an aluminum frame, polymer encapsulants (typically EVA), a polymer backsheet, copper wiring, silver paste, and silicon cells bonded together under heat and pressure.

The challenge in recycling lies in the lamination step used during manufacturing. Once glass, polymers, and cells are fused, separating them without destroying valuable materials requires controlled mechanical breakage, thermal delamination, or chemical dissolution.

Thin-film panels introduce different complications, as they may contain cadmium telluride or copper indium gallium selenide, which require specialized handling.

Material

Crystalline silicon panels

Thin-film panels

Glass

70–75%

85–90%

Aluminum frame

8–10%

0–5%

Polymers

10–12%

5–8%

Silicon or semiconductor layer

3–5%

<1%

Copper and silver

<1%

<1%

Step-by-Step Solar Panel Recycling Process

Mechanical Dismantling and Preprocessing

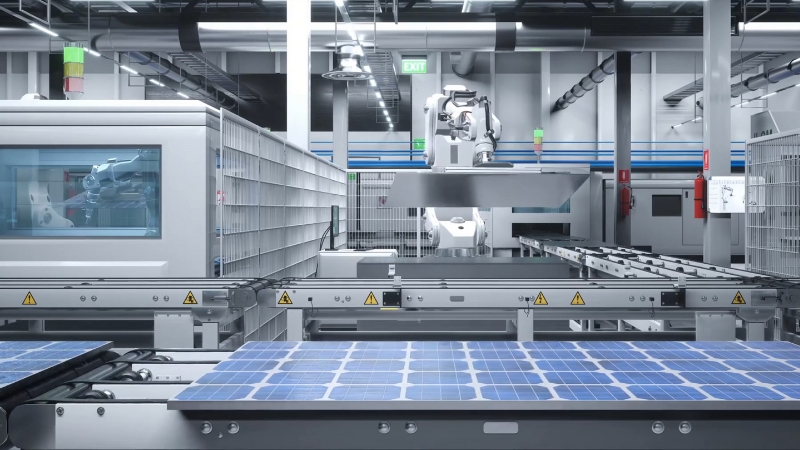

Recycling begins with manual or automated removal of the aluminum frame and junction box. This step alone recovers nearly all aluminum, which is highly recyclable and has a stable scrap market.

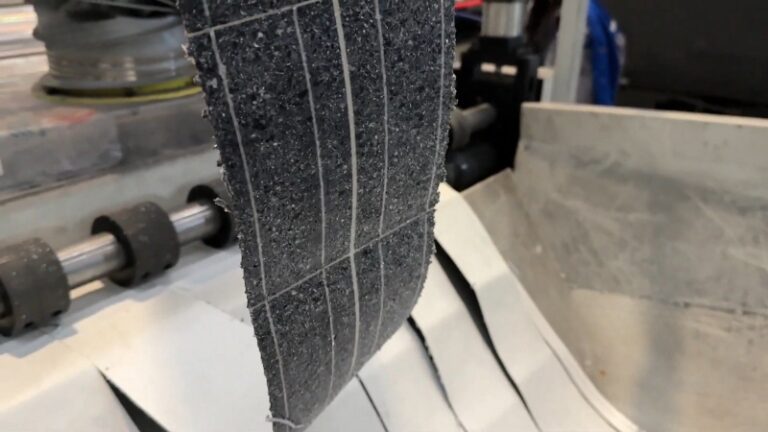

Copper wiring from junction boxes is also removed at this stage. The panel laminate is then crushed or shredded into manageable fragments, usually under controlled conditions to prevent glass dust dispersion.

Mechanical preprocessing typically recovers 100 percent of aluminum, 95 percent of copper, and prepares the remaining laminate for deeper separation. This stage is low-cost and energy-efficient, but cannot separate silicon cells from encapsulants.

Thermal Delamination

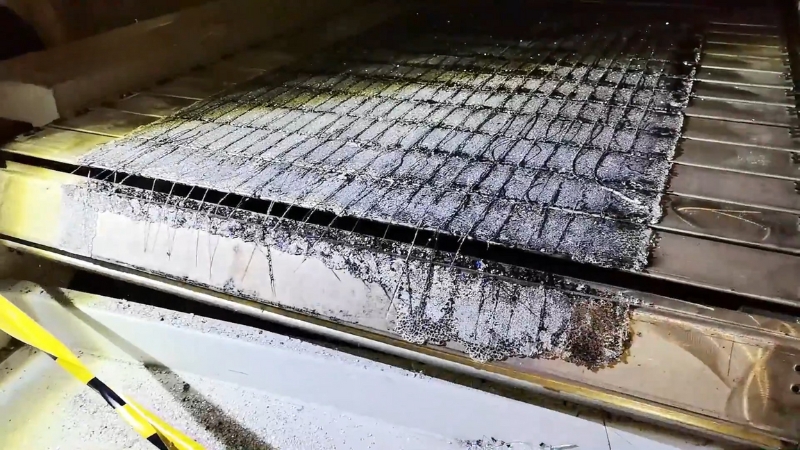

In thermal processes, shredded panel laminates are heated to 450–600°C in oxygen-controlled furnaces. At these temperatures, polymer encapsulants burn off or vaporize without melting glass or silicon. The result is clean glass fragments and intact silicon wafers or cell remnants.

Thermal treatment allows recovery of high-quality glass and silicon suitable for metallurgical reuse, though not typically electronic-grade without further refinement. The main drawback is energy consumption and emissions control, which increase operating costs.

Chemical and Hydrometallurgical Recovery

Advanced facilities use chemical leaching to recover silver, copper, and high-purity silicon from cell remnants. Acids such as nitric or sulfuric acid dissolve metals selectively, while silicon is refined through additional purification steps.

This stage is where most economic value lies, as silver recovery can significantly offset processing costs. However, chemical recycling is slower, more expensive, and tightly regulated due to waste liquid handling.

Process stage

Glass recovery

Metal recovery

Silicon recovery

Mechanical only

85–90%

High for aluminum

None

Mechanical + thermal

90–95%

Moderate

Partial

Full chemical process

95%+

High (Ag, Cu)

High

What Materials are Actually Recovered and Reused

Recovered glass is typically down-cycled into construction glass, insulation, or fiberglass, rather than reused in new solar panels due to purity requirements.

Aluminum frames re-enter standard aluminum recycling streams with minimal losses. Copper is reused in electrical applications with little degradation.

Silicon recovery remains the most technically challenging. Most recycled silicon is currently reused in metallurgical applications or lower-grade solar products, although pilot projects are now producing solar-grade recycled silicon.

Silver recovery rates range from 70 to 95 percent, depending on process sophistication.

Costs of Solar Panel Recycling Today

Solar panel recycling is not free. Costs vary by region, panel type, and regulatory structure. In 2024–2025, typical recycling costs range from $15 to $45 per panel for crystalline silicon modules. Thin-film panels may cost more due to hazardous material handling.

Transport is a significant cost driver, especially in regions without nearby recycling facilities. In some EU countries, recycling costs are prepaid through extended producer responsibility fees, while in the US, costs often fall on system owners or installers.

Cost component

Share of total

Collection and transport

30–40%

Mechanical processing

20–25%

Thermal or chemical treatment

25–35%

Regulatory compliance

5–10%

Recycling Regulations By Region

The European Union treats photovoltaic panels as electronic waste under the WEEE Directive. Manufacturers must finance collection and recycling, ensuring minimum recovery rates of 85 percent by weight.

View this post on Instagram

The United States has no federal solar panel recycling mandate. Regulation is handled at the state level, with states like Washington and California implementing dedicated PV recycling laws. In most states, panels are legally landfillable, though this is changing.

Asia shows mixed approaches. Japan has issued recycling guidelines, but limited enforcement. China is rapidly developing recycling infrastructure due to the scale of its domestic solar installations, with mandatory recycling frameworks expected to expand after 2025.

Regulatory Comparison

Region

Recycling mandatory

Who pays

Landfilling allowed

EU

Yes

Manufacturer

No

USA

Partial

Owner or installer

Often yes

Japan

Limited

Owner

Yes

China

Emerging

Undetermined

Limited

Future Technologies Changing Solar Panel Recycling

Research and pilot facilities are now testing low-temperature delamination, solvent-based encapsulant removal, and closed-loop silicon purification. The goal is to recover materials pure enough to re-enter new panel manufacturing directly.

By 2030, industry analysts expect recycling recovery rates above 95 percent by mass and significantly improved silicon reuse economics. This would shift recycling from a compliance cost to a partially revenue-supported industrial process.

Bottom Line

Solar panel recycling is not primarily an environmental gesture. It is an industrial necessity tied to resource security, waste regulation, and long-term solar economics.

Without recycling, large-scale solar deployment simply shifts material dependency from fossil fuels to mined metals and unmanaged waste. With recycling, photovoltaic energy becomes materially circular, not just low-carbon.

The recycling process is already technically viable. What determines its effectiveness over the next decade is policy enforcement, facility scale, and continued investment in material-grade recovery rather than disposal-focused treatment.