Modern engineering methods have significantly improved the efficiency, scalability, and reliability of clean energy systems.

From optimized wind turbine design to AI-driven grid balancing and advanced solar tracking, today’s technologies allow clean energy to compete with or even outperform fossil fuels in terms of cost and performance.

The most concrete improvements come from better materials, smart control systems, and digital modeling tools that reduce energy loss at every step, from generation to storage and distribution.

In real-world terms, clean energy systems can now reach conversion efficiencies of 45–50% (solar thermal), 98% (hydroelectric), and above 90% for power electronics, thanks to these engineering advancements.

Energy Efficiency Across Clean Technologies

Clean energy systems span multiple technologies – solar, wind, hydro, geothermal, and biomass – each with unique efficiency challenges.

Modern engineering tackles these through digital control, advanced materials, and precision manufacturing.

| Clean Energy Type | Typical Efficiency | Modern Engineering Improvements |

| Wind Power | 35–45% (capacity factor) | CFD modeling, variable-speed generators, and tall tower designs |

| Solar PV | 18–23% (panel) | Multi-junction cells, bifacial panels, and maximum power tracking |

| Solar Thermal (CSP) | 35–50% | Molten salt storage, sun-tracking mirrors, thermal coatings |

| Hydropower | 90–98% | Fish-safe turbines, low-head designs, and dynamic flow control |

| Geothermal | 10–20% | Binary cycle plants, improved heat exchangers, directional drilling |

| Biomass/Biogas | 25–35% | Co-generation systems, fluidized bed combustion, gasification |

Step 1: Computational Modeling and Simulation

Computer-aided engineering (CAE) allows researchers and manufacturers to simulate how a clean energy system performs long before it’s built. In wind energy, for example, computational fluid dynamics (CFD) helps optimize blade shape and placement for maximum output with minimal noise and vibration.

Similarly, in solar farms, modeling tools simulate how sunlight, shading, and temperature changes affect total yield, helping engineers place panels more strategically.

| Method Used | Application Area | Resulting Benefit |

| CFD | Wind turbine design | Increases power output 10–20% |

| Finite Element Analysis | Solar racking structures | Reduces material use while maintaining strength |

| PVsyst/SAM Software | Solar farm layout | Optimizes ROI, energy per m² |

| Power flow simulation | Grid-connected systems | Prevents overloads, reduces curtailment |

Simulations cut trial-and-error costs, speed up development, and ensure that systems run near peak efficiency under real-world conditions.

Step 2: Smart Grid and Digital Controls

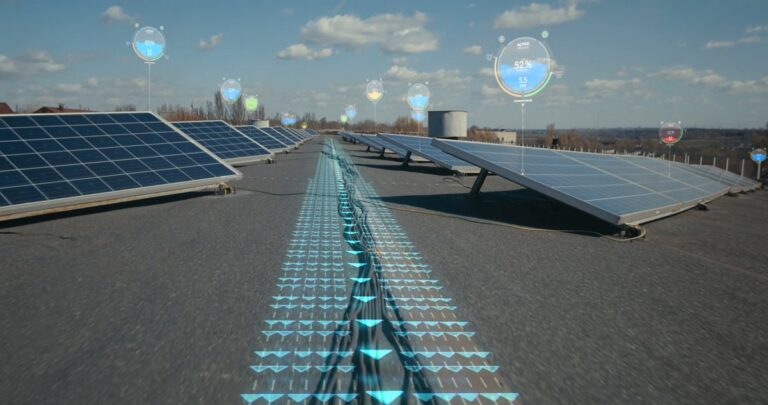

A major shift in clean energy efficiency comes from smart control systems that adjust output, storage, and consumption in real time. These systems rely on sensors, AI, and high-speed data to make micro-adjustments across networks.

For example, solar inverters now include maximum power point tracking (MPPT), which dynamically adjusts voltage to ensure panels always operate at optimal output.

In wind farms, control algorithms monitor wind direction, yaw, and turbine status to shift the generation strategy across the site. On the grid side, AI-powered platforms manage supply and demand, avoiding the need for fossil backup.

| Technology | Function | Efficiency Benefit |

| MPPT Inverters | Optimize solar panel voltage/current ratios | 5–15% output gain |

| SCADA for Wind Farms | Supervisory monitoring of turbine data | Detects faults early, avoids downtime |

| Smart Grid Software | Load balancing, demand response, and automation | Reduces waste, curtailment, and storage needs |

| AI-Based Forecasting | Predict wind/solar availability | Enhances planning, cuts storage costs |

Step 3: Advanced Materials and Coatings

Modern materials engineering has contributed heavily to efficiency gains in clean energy, especially in high-heat or high-wear environments.

Wind turbine blades are now made from carbon fiber composites, which are lighter and stronger than fiberglass, enabling longer blades that capture more energy. In solar thermal systems, specialized coatings on pipes and mirrors reduce reflectivity losses and thermal degradation.

And in battery storage, lithium iron phosphate and solid-state chemistries are improving charge/discharge cycles and round-trip efficiency.

Material advancements have also impacted fluid-handling systems, such as in geothermal plants or biomass facilities, where pumping high-viscosity fluids is often required.

These systems once suffered from major inefficiencies due to friction, heat loss, and wear. Now, modern polymer linings, ceramic bearings, and corrosion-resistant alloys reduce internal resistance and extend the lifespan of pumps.

This makes it far more energy-efficient to circulate thick slurries, bio-oils, or geothermal brines through closed-loop systems, cutting operational costs while improving process uptime.

| Component | Old Material | New Material or Coating | Benefit |

| Wind blades | Fiberglass | Carbon fiber composites | 15–20% lighter, less fatigue |

| Solar thermal pipes | Uncoated steel | Selective absorber coatings | 30–50% more heat retained |

| Grid-scale batteries | Liquid electrolytes | Solid-state ceramics | Longer life, safer operation |

| Solar panels | Aluminum frames | Glass-glass or coated steel | More durable, better temperature stability |

Step 4: Integration of Clean Energy with Heat and Industry

Modern engineering is also improving efficiency by linking clean energy systems to industrial heat applications and district heating. For example, solar thermal collectors can power food processing or textile factories directly, eliminating the need for gas boilers.

In colder regions, heat pumps powered by wind or solar feed into centralized heating networks, displacing oil or coal-based systems.

One notable advancement is the use of induction heat treating powered by solar or hydroelectricity, particularly in precision metalworking industries. This technique uses electromagnetic fields to selectively heat metal parts, reducing the need for large furnaces and minimizing energy waste.

It offers high repeatability and tight thermal control, critical for automotive, aerospace, and tool manufacturing.

Step 5: Modular and Scalable System Design

Engineering innovation also lies in modularity – designing systems that can scale up or down based on demand. Wind farms now use modular inverters, allowing individual turbines to run independently or in clusters.

Solar systems increasingly use microinverters or power optimizers, so each panel performs independently even if others are shaded.

This decentralized approach improves total system efficiency and makes maintenance simpler – technicians can isolate and repair individual units without shutting down the whole plant.

| Modular System Component | Example Technology | Efficiency/Availability Gain |

| Microinverters | Solar panel inverters | 5–25% more energy in mixed light |

| Modular battery banks | Tesla Powerpacks | Isolate faults, scale flexibly |

| Containerized turbines | Offshore wind units | Faster deployment, easier repair |

| Plug-and-play geothermal | Modular heat pumps | Prebuilt kits for faster installation |

Step 6: High-Efficiency Energy Storage

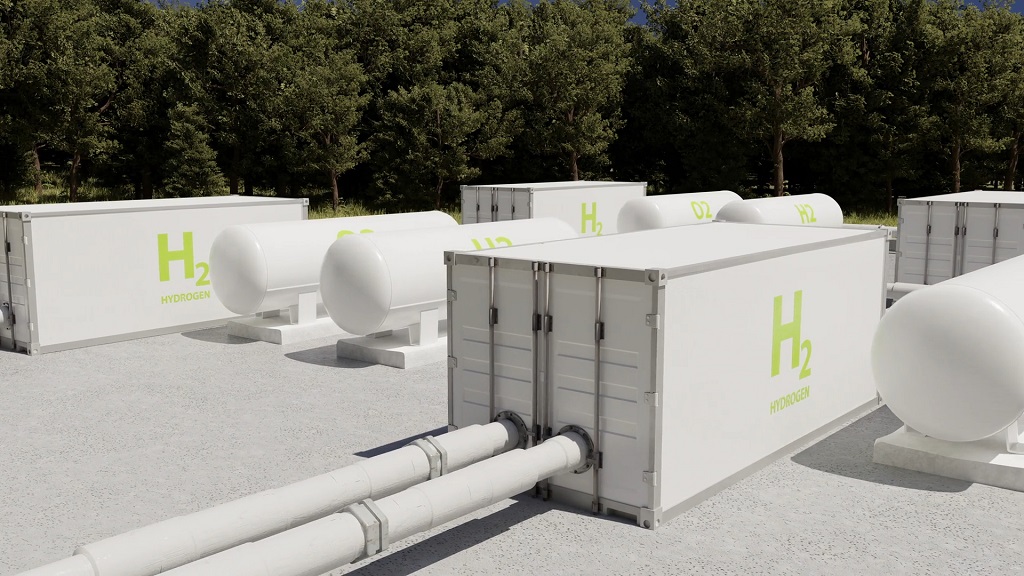

Storage is essential for clean energy, and modern engineering has made huge gains here, too. Today’s batteries, flywheels, pumped hydro, and hydrogen storage systems are all far more efficient thanks to better thermal management, advanced chemistry, and control electronics.

Lithium-ion storage systems now offer round-trip efficiencies above 90%, while thermal energy storage in molten salt tanks (used in solar CSP plants) retains heat for 8–12 hours at over 95% efficiency.

Hydrogen electrolysis systems, once plagued by low yields, now reach 70–80% conversion rates thanks to improvements in electrolyzer design and catalysts.

Final Thoughts

Modern engineering methods are not just tweaking clean energy systems – they’re redefining how efficiently we can generate, store, and use sustainable power.

Through smarter controls, better materials, modular design, and digital simulation, renewable energy now competes with fossil fuels in both cost and performance.

In real-world deployments, these advancements are helping solar farms generate 25% more electricity per acre, wind farms last five years longer, and grid storage systems operate with 90%+ round-trip efficiency. As engineering evolves, clean energy becomes not just cleaner, but smarter, stronger, and more profitable too.