Solar power installations have expanded rapidly across the world, and many of the earliest systems are now approaching 20 to 25 years of operation.

Large numbers of panels will soon reach the end of their expected service life, creating a major disposal and recycling challenge.

Clean energy production has been the primary promise of solar technology for decades, yet panel retirement raises new questions.

Millions of systems will need decisions about replacement, continued operation, or disposal as efficiency declines and warranties expire.

Therefore, it is more than realistic to expect a solar panel retirement crisis in the next couple of years, right?

Today, we will talk about it in greater detail.

How Long Do Solar Panels Actually Last?

Typical solar panel lifespan ranges between 25 and 30 years, and high-quality models can continue producing power even longer. Panels rarely stop functioning suddenly after two decades. Gradual output decline happens instead, meaning many systems remain useful long past the first warranty period.

Performance loss occurs slowly over time, and standard degradation rates tend to remain consistent across most installations.

Average annual reduction typically falls into the following range: 0.5% to 0.8% efficiency loss per year.

Even after decades of exposure to weather, heat, and daily operation, many panels still maintain strong energy production.

Output levels after long-term use often remain substantial: 80% to 90% of original capacity after 25 years, according to Huawei.

Premium panel models perform even better under similar conditions.

- 0.25% to 0.3% reduction per year

- about 92% to 93% efficiency after 25 years

Long service life makes solar energy reliable, yet eventual replacement becomes inevitable as newer technology improves and older systems decline.

What Happens to Solar Panels at Retirement?

Solar panel retirement is becoming a growing issue as early installations reach the end of their expected service life.

Solar energy systems were designed to deliver decades of clean electricity, yet large-scale adoption means millions of panels will eventually require decisions about continued use, replacement, or disposal.

Retirement does not always mean failure. Many panels still operate well, even after warranties expire, which creates a wide range of outcomes for homeowners, businesses, and energy providers.

Retirement decisions are often influenced by efficiency decline, repair costs, advances in newer technology, and the availability of recycling systems. Panel retirement is now emerging as one of the next major challenges tied to renewable energy growth.

Continued Use vs. Decommissioning

Electricity generation often continues well after 25 years, even when panels no longer meet original performance guarantees.

Output may decline gradually, but many systems remain productive long past the warranty period. Owners often face a practical choice between extending system life or investing in replacements.

Several common outcomes shape panel retirement decisions, especially when performance remains usable but not optimal.

- keeping panels active if efficiency still meets household or commercial needs

- upgrading to newer, higher-output technology

- replacing key supporting equipment before removing full arrays

Component replacements often occur before panel removal. Inverters, batteries, and electrical hardware tend to fail sooner than the panels themselves.

Partial system upgrades may happen years before full decommissioning becomes necessary, allowing owners to delay costly replacements.

Decommissioning usually becomes more likely when roof renovations, system expansion, or major efficiency upgrades are planned. Panel removal may also occur when new products offer much better output in smaller footprints.

Current Disposal Outcomes

Disposal practices linked to solar panel retirement remain uneven, mainly because recycling infrastructure has not grown at the same speed as global solar adoption.

Large numbers of retired panels continue to be discarded in landfills, especially in regions without nearby recycling facilities or enforceable end-of-life regulations.

Landfill disposal remains more common than material recovery across many markets, leading to increasing waste and missed recycling potential.

- valuable materials such as glass, silicon, and metals are lost instead of reused

- long-term environmental risk increases if degraded panel elements leach into the soil

Solar panel retirement volumes are expected to rise sharply over the next two decades, making landfill reliance an increasingly unsustainable solution.

Without stronger recycling systems and broader infrastructure development, solar waste could become one of the most pressing long-term challenges tied to renewable energy growth.

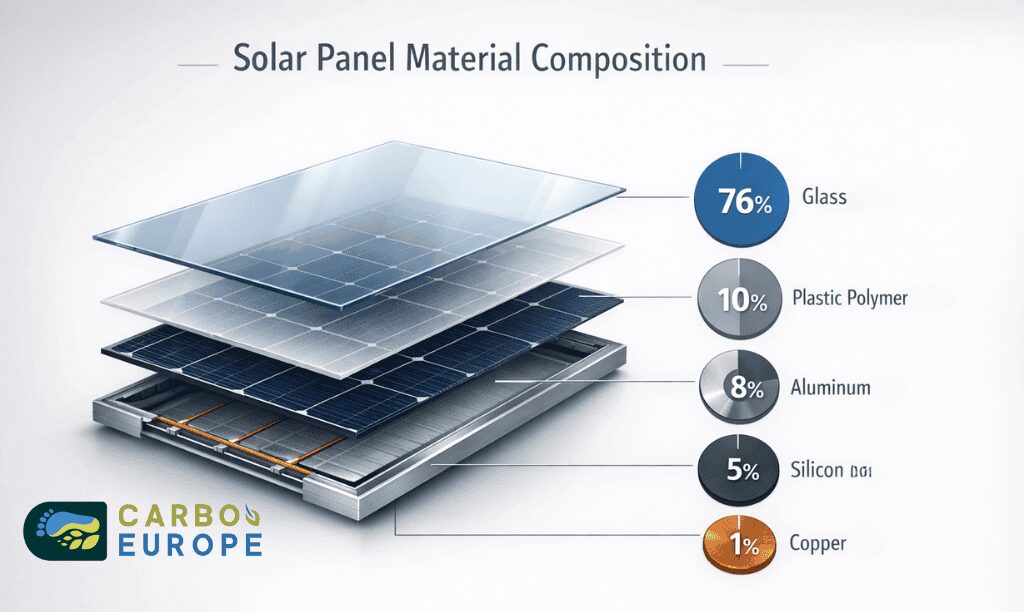

What Are Solar Panels Made Of?

Solar panels are built with layers of durable materials designed to withstand decades of sun, wind, and weather exposure. While panels appear simple on the surface, their internal structure contains multiple recoverable components that require careful separation.

Material composition is distributed across several major categories.

- 76% glass,

- 10% plastic polymer,

- 8% aluminum,

- 5% silicon,

- 1% copper

Glass represents the largest share and offers strong recycling potential. Aluminum frames are also easy to recycle using existing metal recycling systems. Silicon cells contain valuable semiconductor material but require specialized processing.

Plastics add complexity. Encapsulants and backsheets protect solar cells, yet they are difficult to remove and recycle efficiently.

Wiring and junction components also increase recycling value because they contain metals such as copper and silver, though extraction requires advanced separation methods.

Panel design makes recycling challenging because multiple materials are fused for durability rather than easy disassembly.

The Solar Panel Recycling Process

Recycling provides a pathway for retired panels to return valuable materials into manufacturing streams, yet the process remains more complicated than standard glass or metal recycling.

Panel recycling requires multiple stages, each targeting specific materials.

Recycling begins with safe removal and transport, since panels are heavy, fragile, and often installed in large arrays. Proper handling ensures recoverable materials are not damaged during dismantling.

How Panels Are Recycled

De-installation is the first step, followed by careful dismantling to preserve high-value materials.

Frames and external hardware are typically removed early because they can be recycled efficiently through existing infrastructure.

Once panels are separated into basic components, more advanced recovery begins.

- mechanical shredding to break materials into smaller fractions

- thermal treatment to remove plastic encapsulants

- chemical separation to recover semiconductors and precious metals

Each additional step increases processing cost, yet also increases the amount of usable material reclaimed. Advanced recycling systems aim to move panels away from disposal and toward circular reuse.

Materials That Can Be Recovered

Recovery rates depend on facility technology and the type of panel being processed. Glass remains the easiest component to reclaim, while silicon and metals require specialized equipment.

- up to 95% glass recovery

- full recyclability of aluminum frames

- about 85 percent silicon recovery in advanced facilities

Copper and silver extraction adds economic value but remains technically demanding. Recovery success varies depending on separation efficiency, labor requirements, and the cost of chemical processing.

Higher recovery rates become more achievable as recycling capacity grows and economies of scale improve.

Why Solar Panel Recycling Isn’t Common Yet

Despite strong material value, recycling remains limited because economic and logistical barriers still outweigh incentives in many regions. Recycling costs often exceed landfill tipping fees, making disposal the cheaper option.

Infrastructure challenges also restrict growth. Recycling centers are sparse, and retired panels often require long-distance transport.

- limited facilities and high transportation expenses

- panel designs not engineered for easy disassembly

- higher processing costs compared to landfill disposal

Older generations of panels were built primarily for durability and efficiency, not end-of-life separation. Large-scale recycling expansion will require design improvements, regulatory support, and investment in dedicated processing systems.

Environmental Risks of a Growing Solar Waste Stream

Solar panel retirement is expected to generate a rapidly expanding waste stream over the next several decades. As millions of early installations reach end-of-life, disposal volumes will rise sharply. Without major improvements in recycling systems, unmanaged retirement practices could create significant environmental and economic pressure.

Global projections show how large the problem may become, with solar waste potentially reaching up to 80 million metric tons by 2050 if recycling capacity does not improve.

Landfilled panels represent both lost material value and long-term hazard potential. Recoverable components such as glass, silicon, and metals remain trapped in waste sites instead of being returned into manufacturing supply chains.

Environmental risks grow as retired panels sit for long periods and gradually degrade. Large-scale accumulation without proper oversight increases the chance of pollution concerns tied to aging materials.

Long-term solar sustainability depends not only on clean energy production, but also on responsible retirement and end-of-life waste management.

The Road Forward

Mass retirement of early solar installations will create both challenges and opportunities. Recycling technology improvements and economies of scale may allow recovered materials to feed back into solar manufacturing supply chains.

Future progress depends on expanding dedicated recycling facilities and designing panels for easier material recovery. Stronger recycling systems will be essential for managing the coming solar waste surge while maintaining solar energy as a sustainable solution.