Vertical-axis wind turbines offer a fascinating alternative to the more common horizontal designs seen dominating the renewable energy industry.

Their unique configuration, allowing blades to rotate around a vertical axis, opens possibilities in areas where traditional turbines may face limitations.

However, their functionality comes with its own set of challenges, prompting ongoing debates among engineers, environmentalists, and energy planners about their practicality on both small and large scales.

This article will explore the fundamental principles behind vertical-axis wind turbines, shedding light on their strengths in certain applications while addressing the undeniable obstacles that limit their widespread use.

What Are Vertical Axis Wind Turbines?

| Definition | Turbines where the rotor shaft is vertically oriented, unlike the horizontal-axis turbines. |

| Primary Designs | Savonius (drag-based), Darrieus (lift-based), Giromill, and Helical designs. |

| Operational Height | Lower than horizontal turbines, typically closer to the ground or rooftop installations. |

| Suitability | Urban areas, rooftops, or places with turbulent or multidirectional wind flow. |

| Efficiency Range35 | %–40%, depending on the design and wind conditions (compared to 40%–50% for horizontal turbines). |

| Best Use Cases | Small-scale applications, urban setups, and environments where tall structures are not feasible. |

Unlike horizontal-axis turbines, where the blades rotate around a horizontal axis, these turbines function independently of wind direction. This feature makes them advantageous in environments with variable or inconsistent wind patterns.

Applications and Benefits

Vertical axis wind turbines (VAWTs) provide distinct advantages in specific environments and use cases that are not always practical for traditional horizontal axis designs.

Their unique ability to capture wind from any direction without active orientation makes them well-suited for urban, small-scale, and low-wind environments, opening opportunities for renewable energy where large turbines are not feasible.

Key Application Areas

Urban and Residential Environments

One of the most compelling applications for vertical turbines is in dense urban areas, where wind flow is often turbulent, multidirectional, and inconsistent due to the presence of buildings and infrastructure.

Unlike horizontal turbines, which require reorientation to align with prevailing winds, vertical turbines operate efficiently in these conditions.

Rooftops in cities like New York, London, and Tokyo have tested VAWTs to complement solar panels, providing additional renewable energy sources for apartment buildings, schools, and small offices.

Their low noise levels make them suitable for residential areas, avoiding complaints that often accompany traditional wind turbines.

Small-Scale Power Generation

VAWTs excel in small-scale power applications, where installing large horizontal turbines is neither practical nor cost-effective. These turbines can be deployed to power LED streetlights, signage, water pumps, or small-scale off-grid homes without requiring significant land use or tall structures.

Their compact and modular designs allow them to be installed quickly and integrated into existing infrastructure with minimal modifications, making renewable energy adoption easier for homeowners and small businesses.

Solar-powered pumps provide reliable and cost-effective access to water — improving lives & decarbonising agriculture https://t.co/n6bzvAKySz #Renewables4Development

— IRENA (@IRENA) August 24, 2018

Remote and Off-Grid Locations

In remote or off-grid locations, VAWTs can provide essential power where extending electrical grids is impractical or too expensive. Their simple construction and low maintenance requirements make them viable for telecom towers, monitoring stations, and rural electrification projects in developing regions.

Supplementary and Hybrid Renewable Systems

Vertical turbines are often used alongside solar panels in hybrid renewable energy systems. While solar panels provide energy during sunny conditions, vertical turbines generate power when it is cloudy and windy, ensuring energy availability across different weather conditions.

Design Features

Vertical turbines often have a simpler construction. The generator and gearbox are located near the base, which simplifies maintenance and reduces structural demands.

However, their proximity to ground-level wind streams – typically slower and more turbulent – limits their power output.

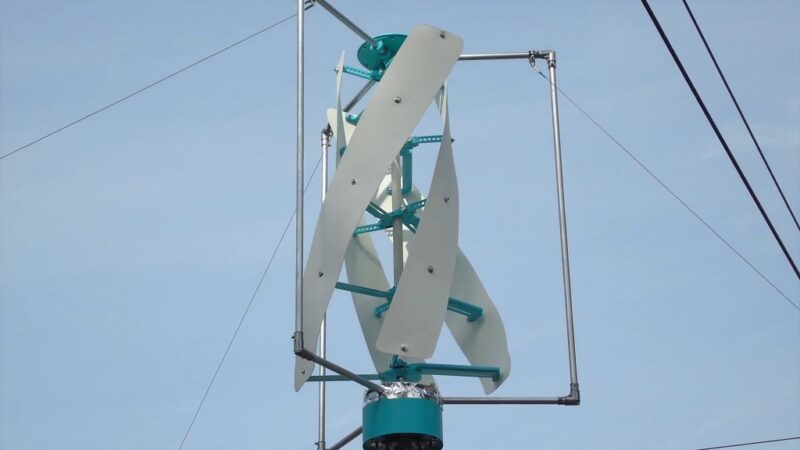

Savonius turbines, with their bucket-like design, excel in small-scale applications, such as powering streetlights or rooftop installations.

Darrieus models, shaped like an eggbeater, offer higher efficiency but require a starting mechanism due to their inability to self-start in low winds.

Limitations

Real efficiency rates for vertical-axis wind turbines hover between 35%–40%, significantly lower than horizontal-axis systems, which achieve around 40%–50% efficiency.

This discrepancy is primarily due to drag forces acting against some blades during rotation. Moreover, vibration issues and material stress have historically led to higher maintenance costs.

The overall wind turbine market size surpassed USD 141.4 million in 2023 and is predicted to grow at over 8.2% CAGR from 2024 to 2032.

Lower Energy Conversion Efficiency

Vertical-axis wind turbines (VAWTs) generally achieve efficiency levels in the range of about 35% to 40%, which is typically lower than the 40% to 50% efficiency commonly reached by horizontal-axis wind turbines (HAWTs). This difference stems largely from aerodynamic limitations inherent to vertical designs.

In a VAWT, blades rotate around a vertical shaft and inevitably pass through positions where they encounter the wind at suboptimal angles. Some blades are effectively moving into the wind while others move away from it during each rotation cycle, which reduces net energy extraction.

Additionally, most VAWT designs rely partly on drag forces rather than pure aerodynamic lift. Lift-based systems, such as modern horizontal turbines, extract energy more efficiently because they convert airflow momentum with less resistance.

The mixed drag-lift interaction in VAWTs leads to energy losses that prevent them from achieving the same aerodynamic performance as large horizontal machines, especially in steady, high-speed wind conditions.

Drag Forces and Mechanical Stress

Because vertical turbines rotate in a cylindrical path rather than facing the wind directly, a portion of the blade rotation always occurs against the wind direction.

This produces aerodynamic drag that not only reduces energy capture but also introduces uneven torque loads on the rotor shaft.

The alternating forces can cause cyclical stress on components, which influences durability and long-term reliability.

These drag forces also limit maximum rotational speed compared with horizontal turbines. Reduced rotational speed directly affects generator output and overall power production.

In low or moderate wind conditions, this effect becomes more pronounced because the turbine cannot maintain the optimal tip-speed ratios necessary for efficient electricity generation.

Furthermore, uneven aerodynamic loading can lead to vibration patterns that must be carefully managed through engineering design, materials selection, and mounting systems.

Without adequate structural damping, these forces can accelerate fatigue in blades, joints, and transmission components.

Maintenance Requirements and Component Wear

VAWTs are often positioned closer to ground level, particularly in urban or small-scale installations. While this placement simplifies installation and maintenance access, it also exposes turbines to more turbulent airflow caused by buildings, trees, and terrain features.

Turbulent wind conditions produce fluctuating loads on turbine components, increasing vibration intensity and mechanical fatigue.

Bearings, blade connections, and shafts in vertical turbines may therefore experience accelerated wear compared with turbines installed in stable, high-altitude wind streams.

Regular inspection cycles, lubrication schedules, and structural monitoring become critical to maintaining operational safety and efficiency.

In addition, some VAWT designs use guy wires or additional structural supports to maintain rotor stability. These extra components add maintenance complexity and potential failure points that must be monitored over time.

Structural Scaling Challenges

Vertical turbines function well at small or medium scales, particularly where wind direction is inconsistent or space is limited. However, scaling them to utility-scale power production introduces significant engineering challenges.

Large VAWTs must withstand complex aerodynamic loads acting across the entire rotor height rather than primarily at the hub as in horizontal turbines.

Material fatigue, blade deformation, and tower stability become more difficult to manage as turbine size increases. Heavier rotors demand stronger bearings and support structures, which increase cost and complicate installation.

Structural resonance and vibration amplification are also greater risks in larger vertical designs, requiring sophisticated damping solutions.

These engineering barriers partly explain why most large wind farms favor horizontal-axis turbines despite the operational advantages VAWTs may offer in certain environments.

Reduced Access to Strong, Stable Wind Resources

Wind speed typically increases with altitude due to reduced surface friction. Horizontal-axis turbines are usually mounted on tall towers specifically to capture these stronger, more consistent wind flows.

Vertical turbines, especially those designed for distributed or urban deployment, are often installed at lower heights where wind speed is weaker and more variable.

Lower wind speeds translate directly into reduced power output because wind energy increases exponentially with velocity. Even small differences in average wind speed can significantly affect annual energy production.

Additionally, ground-level turbulence can disrupt airflow continuity, further reducing efficiency and increasing mechanical stress on turbine components.

This limitation makes VAWTs more suitable for localized or supplemental energy generation rather than large-scale grid supply in most cases.

Advantages of Vertical Axis Wind Turbines

| Omnidirectional | Can capture wind from any direction without the need for reorientation, making them suitable for turbulent wind conditions. |

| Lower Noise Levels | Operates more quietly compared to horizontal axis turbines, ideal for residential and urban areas. |

| Smaller Footprint | Can be installed closer together in arrays, requiring less land for wind farms. |

| Maintenance Accessibility | The generator and gearbox are located at the base, making maintenance simpler and safer. |

| Adaptability | Can function in low wind speeds and variable weather conditions, providing consistent power output in diverse environments. |

Vertical-axis wind turbines offer several unique advantages over horizontal-axis designs, particularly in settings where space, noise, or turbulent wind conditions are a concern.

These turbines can operate efficiently in urban and residential areas where omnidirectional wind flow is common.

Unlike horizontal-axis turbines that require active alignment with wind direction, vertical turbines harness energy regardless of wind orientation, reducing complexity and increasing reliability.

Specific Benefits

- Ease of Installation: Their smaller size and modular designs make them more adaptable for rooftop and small-scale installations. This feature is particularly valuable for individuals or businesses looking to adopt renewable energy without major infrastructure changes.

- Safety for Wildlife: Vertical-axis turbines operate with low-speed blades, reducing the risk of harm to birds and bats. A study published in Renewable Energy in 2022 noted that urban installations of these turbines caused significantly fewer wildlife disturbances compared to traditional models.

- Cost Efficiency in Small Applications: Manufacturing costs for vertical-axis turbines are often lower for small-scale models due to the simpler construction and reduced materials required.

In 2016, IceWind, in collaboration with AFA JCDecux Iceland and the City of Reykjavik, introduced the “Storm Shelter”—a bus stop in central Reykjavik equipped with two customized vertical-axis wind turbines.

Problems with Vertical Axis Wind Turbines

| Lower Efficiency | Vertical axis turbines typically convert only 35%–40% of wind energy into electricity, compared to 40%–50% for horizontal axis turbines. |

| Drag Forces | Some blades face drag during rotation, which reduces efficiency and increases mechanical strain. |

| Maintenance Costs | Vibration and turbulence near ground level can lead to frequent wear and tear, increasing the need for repairs. |

| Structural Challenges | Scaling up vertical-axis turbines to larger sizes introduces design complications, including material stress and blade stability. |

| Limited Wind Speed Access | Being closer to the ground, vertical turbines miss out on stronger and more consistent winds available at higher altitudes. |

Vertical-axis wind turbines face significant technical and operational challenges that limit their broader adoption in the renewable energy sector. One major drawback lies in their efficiency.

Unlike horizontal-axis turbines, which optimize blade positioning to harness maximum wind energy, vertical-axis models encounter drag as certain blades rotate against the wind.

Efficiency Limitations

The Betz Limit, which defines the maximum theoretical efficiency of wind turbines, is often unattainable for vertical-axis turbines due to the drag created by blades moving against the wind.

Drag Forces Reduce Effectiveness

A key challenge for vertical turbines is the drag forces acting on the blades during rotation.

Unlike horizontal turbines, where blades are continuously oriented to harness wind flow, VAWT blades spend part of each rotation cycle moving directly into the wind, which creates resistance and reduces net rotational energy.

This drag not only lowers the overall efficiency of the turbine but also contributes to increased mechanical stress on the blades and supporting structures, requiring designs to account for these additional forces during operation.

Maintenance Demands

Vertical-axis turbines generally require more frequent maintenance than horizontal turbines due to their operational environment and mechanical design.

Since VAWTs are positioned closer to the ground, they operate in areas with turbulent and variable wind patterns, which cause vibrations that increase wear on bearings, shafts, and blades.

These vibrations can lead to premature mechanical failures if not addressed, making regular inspections and maintenance critical for maintaining performance and extending the operational lifespan of the turbine.

Additionally, while ground-level access makes maintenance easier, the need for more frequent interventions can increase operational costs over time.

Limited Wind Access

Another significant limitation of vertical turbines is their reduced access to high-speed, stable winds. Horizontal axis turbines are mounted on tall towers specifically to capture stronger and more consistent wind flows found at higher altitudes.

In contrast, VAWTs are typically installed at lower heights due to their design and intended use cases, which means they often operate in slower and more turbulent wind conditions near the ground.

This limitation further restricts their ability to generate high levels of power output consistently, making them less suitable for utility-scale energy generation where maximizing energy capture is crucial.

Vertical vs. Horizontal Wind Turbines

| Aspect | Vertical Axis Wind Turbines (VAWTs) | Horizontal Axis Wind Turbines (HAWTs) |

|---|---|---|

| Design | Blades rotate around a vertical axis. The generator and gearbox are typically located near the base. | Blades rotate around a horizontal axis. The generator and gearbox are mounted at the top of the tower. |

| Wind Direction | Captures wind from any direction without reorientation. | Requires alignment with wind direction for maximum efficiency. |

| Efficiency | Lower efficiency | Higher efficiency |

| Installation | It can be installed closer to the ground or on rooftops. | Requires taller towers for optimal wind capture. |

| Maintenance | Simpler, as major components are located at ground level. | More complex, with components located at the top of the tower. |

| Applications | Best for small-scale, urban, or turbulent wind environments. | Ideal for large-scale energy production, such as wind farms. |

Design Differences

Vertical-axis wind turbines feature a design where the blades spin around a vertical shaft. This allows them to capture wind from any direction without requiring adjustments.

In contrast, horizontal turbines have a more aerodynamic design that demands alignment with the wind direction, achieved through yaw mechanisms.

Efficiency Comparison

Horizontal turbines are more efficient, converting up to 50% of wind energy into electricity. This is due to their optimized blade design, which minimizes drag and maximizes lift.

So you might be able to charge your Tesla with it.

Vertical turbines, on the other hand, struggle with drag forces as some blades move against the wind during rotation, leading to a lower energy conversion rate.

Installation and Maintenance

View this post on Instagram

Vertical-axis wind turbines are generally easier and less expensive to install due to their compact size and ground-level mechanical components. The generator and gearbox in a VAWT are located near the base, eliminating the need for tall towers or cranes during installation and making repairs accessible without specialized equipment.

This ease of access reduces both initial setup costs and ongoing maintenance expenses, making vertical turbines a practical choice for urban environments, rooftops, and small-scale renewable projects where simplicity and space constraints are factors.

In contrast, horizontal-axis wind turbines require taller towers to reach higher altitudes, where wind speeds are stronger and more consistent. This need for height increases the complexity of installation, often involving large cranes, heavy foundations, and specialized crews.

Maintenance for horizontal turbines can also be more challenging since critical components like the gearbox and generator are located at the top of the tower, requiring technicians to work at significant heights.

However, these added complexities are justified by their ability to generate significantly higher energy output, making them ideal for large-scale wind farms and utility-level energy production.

Applications

Vertical turbines excel in environments where wind conditions are turbulent or multidirectional, such as in cities or on rooftops surrounded by buildings that disrupt consistent airflow.

Their ability to capture wind from any direction without reorientation makes them well-suited for urban renewable energy projects and off-grid small-scale applications.

Additionally, their quieter operation and lower visual impact make them preferable in areas where aesthetics and noise concerns are important, such as residential neighborhoods, schools, and public spaces.

Horizontal turbines dominate the landscape of industrial-scale renewable energy generation. Their design and taller structures allow them to harness steady, high-speed winds found in open plains, coastal regions, and offshore sites efficiently.

Because they can capture more energy per unit area and operate with higher efficiency, horizontal turbines are the preferred option for wind farms seeking maximum energy output, supporting utility grids with large-scale, cost-effective clean energy.

Where Vertical Axis Wind Turbines Work Best?

| Urban Environments | Omnidirectional design captures turbulent and variable winds effectively. Suitable for rooftops and small spaces. |

| Small-Scale Power Needs | Lower cost and ease of installation make them practical for residential use, small businesses, or powering signage. |

| Remote Locations | Simple designs work well in areas with limited infrastructure for maintenance, such as rural or off-grid sites. |

| Low Wind Speed Areas | Capable of operating in environments where wind speeds are variable or inconsistent. |

| Noise-Sensitive Areas | Operate more quietly than horizontal turbines, making them ideal for residential neighborhoods or parks. |

Rooftop installations in areas like New York City or Tokyo have explored small-scale vertical turbines as a way to complement solar panels in generating renewable energy.

In remote locations like rural areas of India or Africa, vertical turbines are often used for basic power needs such as water pumping or powering small devices.

Practical Applications

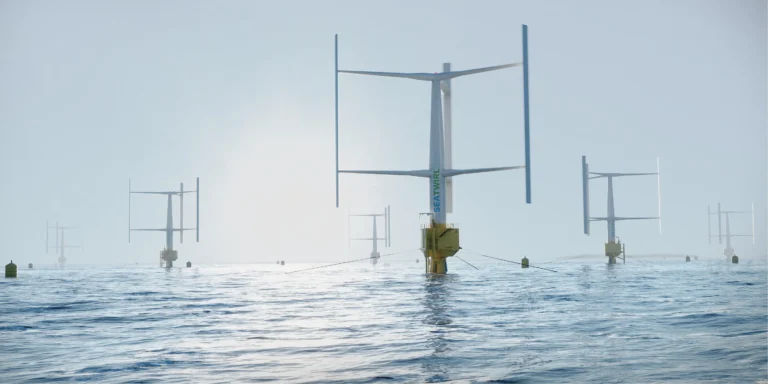

- Offshore Testing: Vertical turbines have been trialed for use on floating offshore platforms due to their low center of gravity and simpler anchoring requirements compared to horizontal turbines. While they are not yet widely deployed in these environments, early results show potential for improving energy capture in turbulent marine wind conditions.

- Rural Electrification: Small farms in areas like central Europe and remote parts of the U.S. have successfully used vertical turbines to power small-scale operations, such as livestock monitoring equipment or greenhouse fans.

- Supplementary Systems: Vertical turbines are often paired with solar energy in hybrid renewable systems. For example, a community in Germany installed vertical turbines on rooftops alongside solar panels, ensuring energy availability during both sunny and windy conditions.

Let’s Check the Latest Innovations

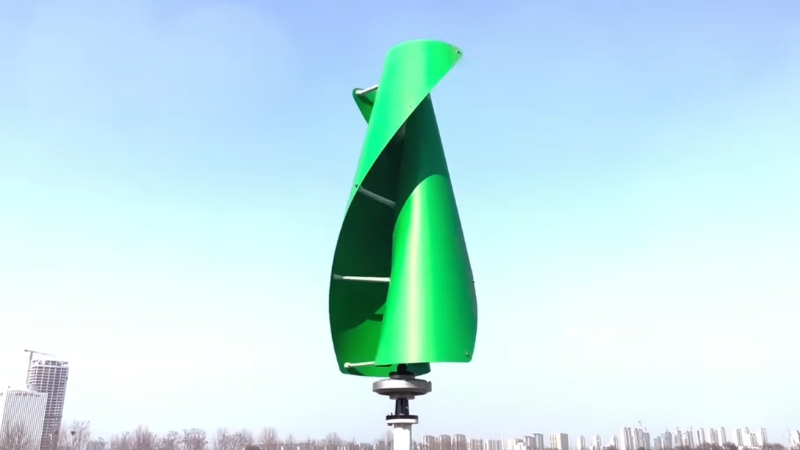

| Helical Blade Design | Blades with a helical twist reduce drag and improve energy efficiency by maintaining consistent aerodynamic performance. |

| Advanced Materials | Lightweight composites and reinforced materials increase durability while minimizing structural stress. |

| Counter-Rotating Systems | Two turbines rotating in opposite directions balance forces and enhance energy capture from the same wind source. |

| Integrated Hybrid Systems | Combining vertical turbines with solar panels or battery storage ensures continuous power availability. |

| Smart Monitoring | IoT-enabled sensors track performance and predict maintenance needs, reducing operational costs. |

One of the most notable advancements in vertical turbines is the introduction of helical blades, which are shaped like DNA strands.

Modern vertical turbines use advanced composites like carbon fiber and high-strength polymers, which improve durability while keeping the structure lightweight.

Some designs incorporate counter-rotating turbines, where two sets of blades rotate in opposite directions.

IoT-enabled sensors and software are transforming the maintenance of vertical turbines. These systems monitor vibrations, blade stress, and energy output in real time, allowing operators to predict maintenance needs and avoid costly downtime.

FAQs

Last Words

@voxivet0903530951 wind turbine vertical 200kw #diengiovietnam #nangluongtaitao #windturbine ♬ nhạc nền – võ xiêm

Vertical-axis wind turbines offer a unique approach to renewable energy, with their omnidirectional design and ability to operate in diverse settings. They excel in urban environments, small-scale installations, and areas where traditional horizontal turbines face limitations.

Advances in helical blade designs, lightweight materials, and hybrid energy systems have addressed some historical challenges, making them increasingly viable in niche markets.

As renewable energy technology continues to evolve, vertical-axis wind turbines may find broader use, especially with ongoing improvements in performance and adaptability.

Their value lies in complementing existing energy systems, filling gaps where traditional designs fall short, and contributing to a more sustainable future.

References

- What is a Savonius wind turbine (ScienceDirect Topics)

- Dornier Darrieus Savonius 5.5 kW turbine model (Wind Turbine Models)

- Vertical-axis wind turbines work well together (ASME)

- Wind turbine market size report (Global Market Insights)

- Wind energy advantages and disadvantages (CarboEurope)

- Betz limit explained (Energy Education)

- Vertical turbines harness wind regardless of orientation (ADBI working paper PDF)

- AFA JCDecux Iceland (project site)

- FAO document on renewable-powered water pumping (PDF)

- Vertical axis wind turbines overview (Windpower Engineering)

- Cost to fully charge a Tesla (CarboEurope)

- IoT-enabled system for monitoring and controlling vertical farming operations (ResearchGate)